Latest News

Merry Christmas

December 15, 2023

Wishing you a Merry Christmas & a Happy New Year, from everyone at CEEP Connectors Limited 🎄

Success at Ocean Business

June 13, 2023

A successful 3 days at Ocean Business. We enjoyed every moment of it. Thank you to Cheri and her team for organising such a great event. We look forward to seeing everyone again in 2025

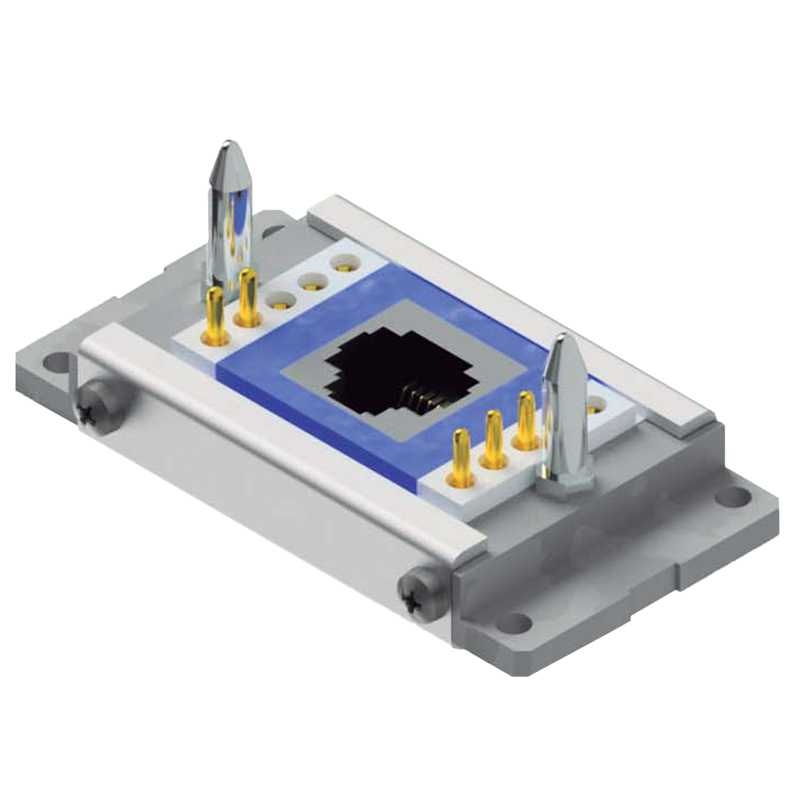

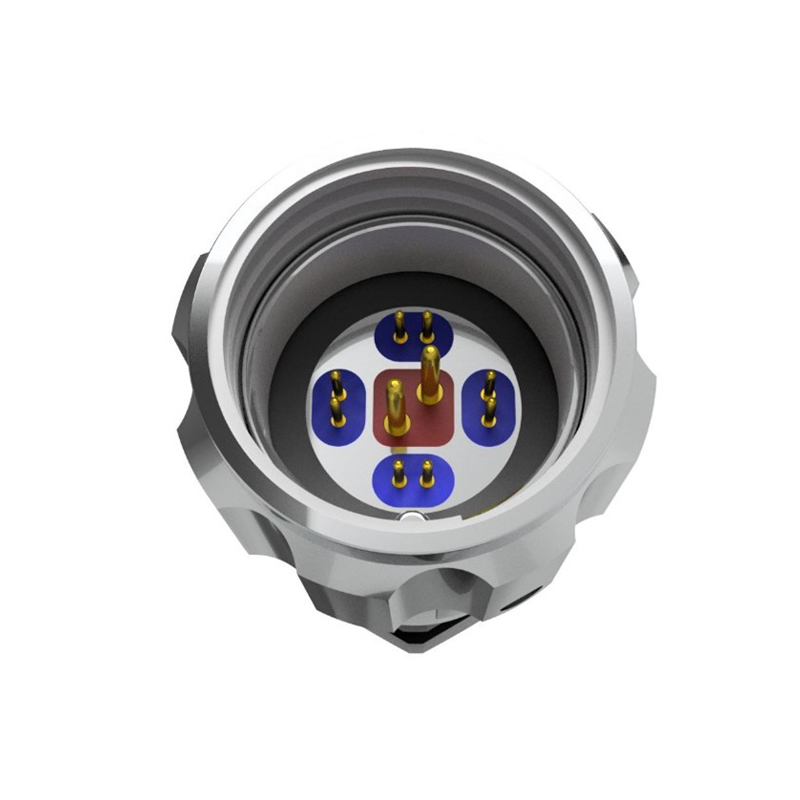

Ocean Business 2023

March 31, 2023

We will be exhibiting at Ocean Business, Southampton next month. Join us on stand V9 to discuss your IP68 connector requirements. We look forward to seeing you all 🐟 #oceanbusiness #OB23 #IP68connectors

CEEP Prosper

September 8, 2022

CEEP Prosper We are proud to announce the sponsorship of a young and dynamic company. A local team that share the same values and work ethics as us. Supports and encourages the development of all involved. Prosper Performance Coaching is a football coa …

Success at Seawork

June 17, 2022

A big THANK YOU to everyone who visited our stand at Seawork Southampton this week. It was great seeing you all. This weekend will certainly be spent recovering! 😄 #seawork2022 #IP68connectors #marineconnectors